In the world of automated material handling, the term “Standard Pitch” is frequently used by engineers and procurement managers. But what exactly makes a belt “standard,” and why is it the backbone of thousands of production lines worldwide?

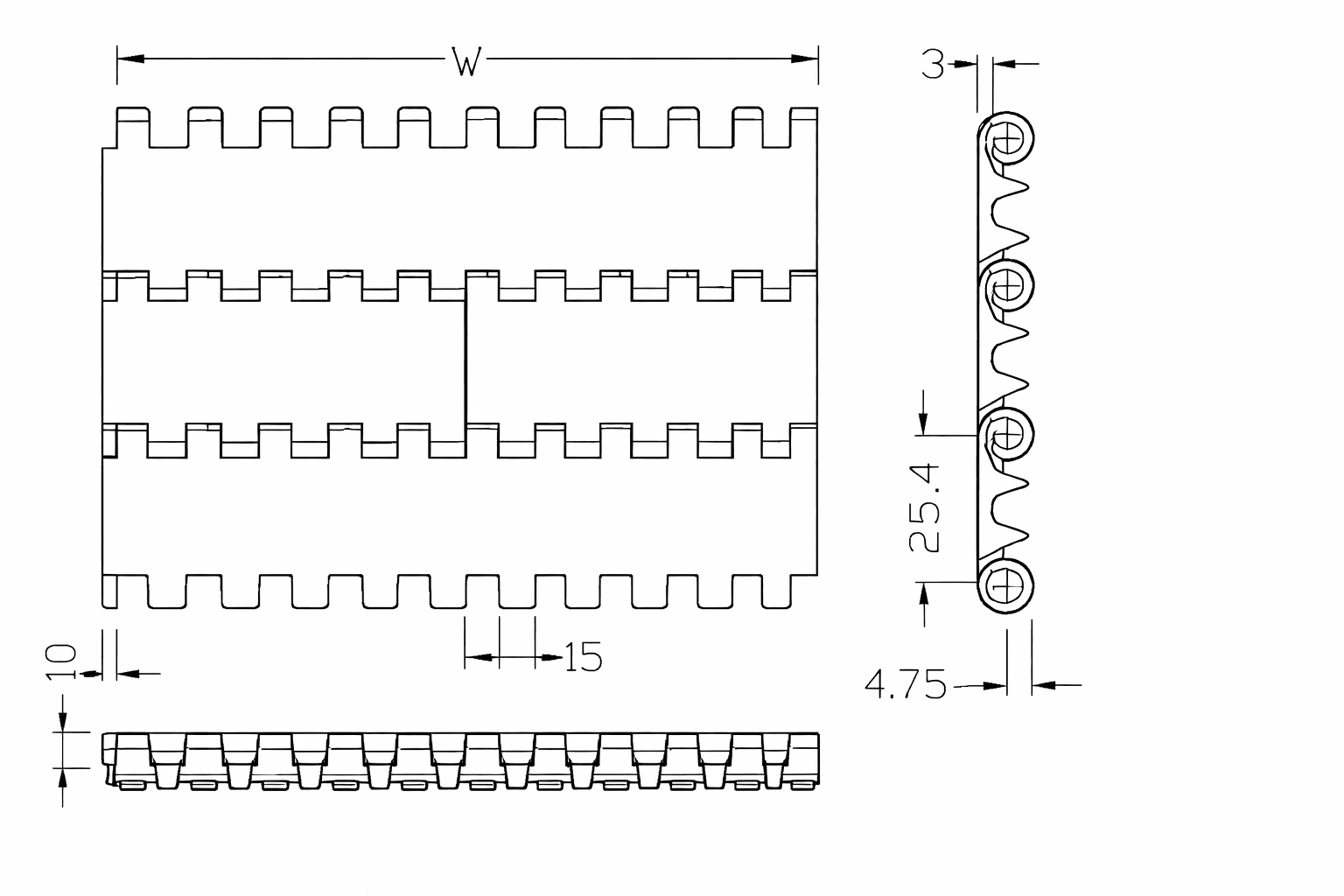

If you are at the early stages of designing a conveyor system or looking for a replacement, understanding the standard pitch modular belt (Pitch :1inch)is your starting point for a reliable and cost-effective operation.

1. What Does “Standard Pitch” Mean in Modular Belts?

In the context of modular plastic belts, “pitch” refers to the center-to-center distance between the hinge pins that connect the individual modules.

أ standard pitch modular belt typically refers to the 1-inch (25.4 mm) أو 2-inch (50.8 mm) series. These sizes have become the industry benchmark because they offer the optimal balance between:

قوة الشد: Large enough pins to handle heavy loads.

التنوع: Compatible with a wide range of standard sprockets and drive components.

Ease of Maintenance: Large modules are easy to handle and clean during routine inspections.

2. Typical Applications of Standard Pitch Modular Belts

Because of their robust nature, standard pitch belts are the “workhorses” of the conveying world. You will most commonly find them in:

Automotive & Heavy Manufacturing: Moving heavy parts or assemblies through the plant.

Fruit & Vegetable Processing: Handling bulk produce where large drainage areas (open grids) are required for washing.

الخدمات اللوجستية والتخزين: Transporting boxes, crates, and large parcels over long distances.

Large-Scale Packaging: Where the primary goal is moving heavy secondary packaging (like cardboard cases) rather than delicate individual items.

3. Why Standard Pitch Is Still Widely Used

Despite the emergence of specialized belts, the 1-inch and 2-inch series remain the go-to choice for several reasons:

Cost-Efficiency: Due to mass production, standard belts are generally more budget-friendly than custom or fine-pitch alternatives.

مصداقية: Their thicker hinges and pins provide a higher safety factor for heavy-duty applications or high-torque environments.

Standardization: Using standard components simplifies your inventory. One type of sprocket or module can often be used across multiple lines in your facility.

4. Standard Pitch vs. Fine Pitch: Key Differences

While standard belts are excellent for bulk and heavy items, they aren’t always the right fit for every task. Here is a quick comparison to help you categorize your needs:

| ميزة | Standard Pitch (1″+) | Fine/Small Pitch (<0.5″) |

| Primary Goal | High Strength & Bulk Movement | Precision & Delicate Handling |

| Transfer Type | Requires transfer plates/rollers | Tight “Nose-Bar” transfers |

| Product Size | Large boxes, heavy parts | Vials, snacks, small electronics |

| Sprocket Size | Large diameters | Small/Compact diameters |

If your product is smaller than a business card or requires extremely smooth movement without “chordal action” (vibration), you may need to look beyond the standard series.

5. Conclusion

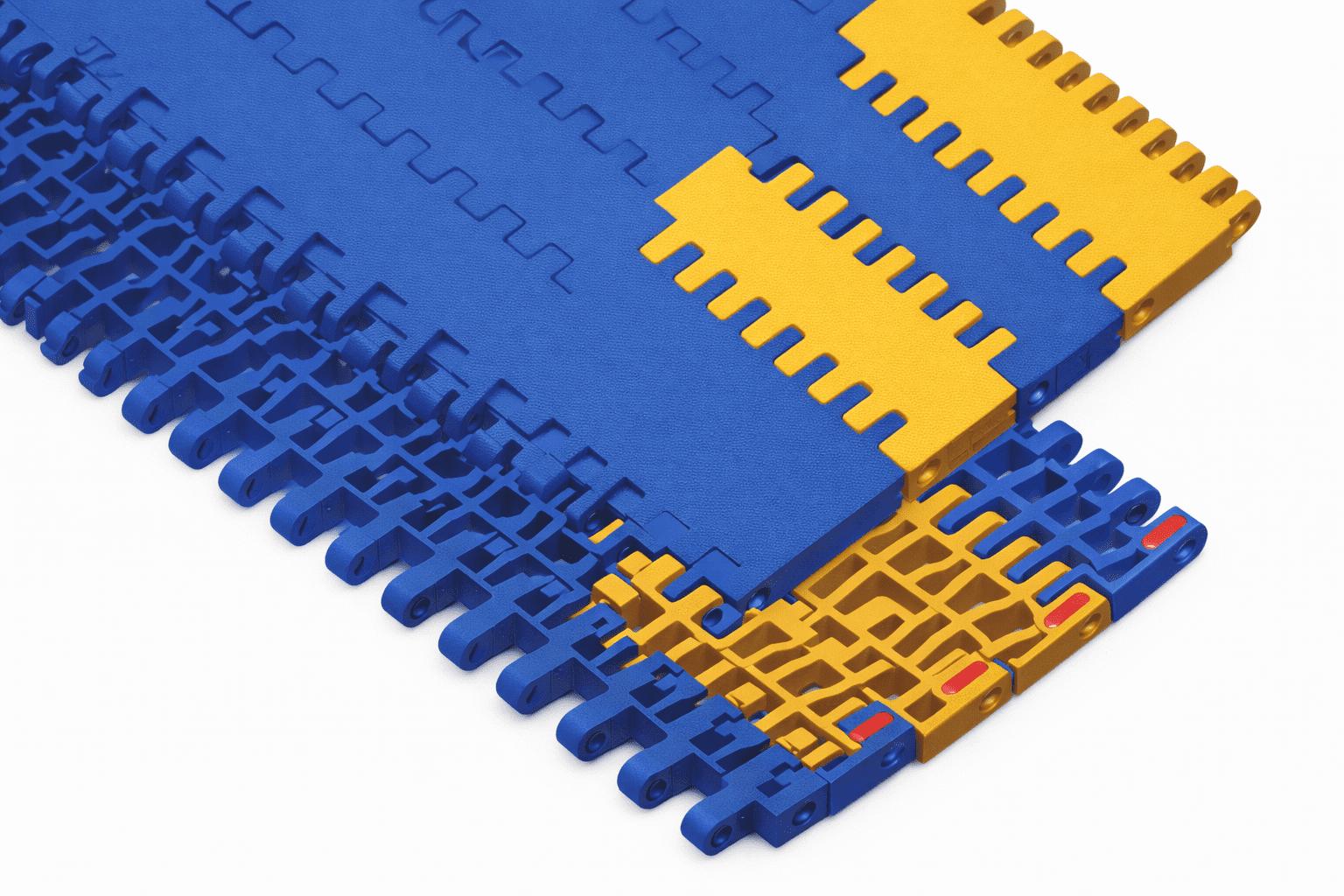

ال standard pitch modular belt remains the industry standard for a reason: it works. It provides the durability and simplicity needed for the majority of industrial conveying tasks. However, the first step in a successful conveyor design is knowing whether your product requires this “standard” strength or the “fine” precision of a smaller pitch.

Looking for a reliable, industry-standard solution?

Explore our high-durability 1-inch series designed for maximum uptime and easy maintenance.

👉 [Browse Our Standard Pitch Modular Belt (1-Inch Series)]

Related Blog :Standard Pitch vs. Small Pitch Modular Belt: Which One Do You Really Need?