مقدمة

في خطوط التعبئة والتغليف الحديثة، آلة عد الأكياس الأوتوماتيكية—وتسمى أيضًا آلة فرز الأكياس—مُعدة أساسية لتعزيز الكفاءة وخفض التكاليف. ولكن مع توافر هذا الكمّ الهائل من النماذج والحلول التقنية في السوق، كيف تختار الأنسب لاحتياجاتك الإنتاجية؟

اختيار النموذج المناسب أمر بالغ الأهمية. فالاختيار الصحيح يُحسّن الإنتاج بشكل ملحوظ، ويُخفّض تكاليف العمالة، ويضمن جودة ثابتة. أما الاختيار الخاطئ، فقد يُؤدي إلى هدر الاستثمار ويُسبب اختناقات تُبطئ خط الإنتاج بأكمله.

يوفر هذا الدليل إطار عملي للاختيار خطوة بخطوة—تغطية عوامل القرار الرئيسية والمقارنات الفنية ودراسات الحالة الحقيقية—حتى تتمكن من اتخاذ خيار واثق ومستنير.

الفصل الأول: العوامل الأساسية التي يجب مراعاتها عند اختيار آلة عد الأكياس

1.1 خصائص المنتج

قبل النظر إلى النماذج، قم بتحليل مواصفات منتجك بالتفصيل:

- نطاق حجم الكيس لكل طراز نطاق طول محدد. على سبيل المثال، يُناسب الطراز FL10-1800 أكياسًا بمقاس 85-168 مم، بينما يُناسب الطراز FL10-2800 أكياسًا بمقاس 145-290 مم. إذا كانت مجموعة منتجاتك واسعة، فقد تحتاج إلى طراز بنطاق أوسع أو عدة آلات.

- المواد والسمك – قد تتطلب الأكياس البلاستيكية الخفيفة ميزات مضادة للكهرباء الساكنة، وتحتاج الأكياس المصنوعة من رقائق الألومنيوم الثقيلة إلى سعة دفع أقوى، وقد تحتاج الأكياس الورقية إلى معالجة أكثر لطفًا.

- الوزن والكثافة – تتطلب المنتجات الأثقل محركات وإطارات أقوى، في حين أن الأكياس الخفيفة جدًا قد تنجرف بسرعات عالية دون أنظمة تحديد المواقع الدقيقة.

- الشكل والمرونة - الأكياس المسطحة والمستطيلة أسهل في التعامل من الأكياس غير المنتظمة أو الناعمة، والتي قد تتطلب محاذاة وتحكمًا متقدمين.

1.2 متطلبات الإنتاج

إن سرعة إنتاجك وحجمك اليومي وساعات التشغيل تحدد السعة التي تحتاجها.

- مطابقة السرعة يجب أن تتناسب الآلة على الأقل مع سرعة خط التعبئة والتغليف لديك. على سبيل المثال:

- سلسلة FL10: 80–120 كيسًا/دقيقة (على نطاق صغير إلى متوسط)

- سلسلة FL14: 100–120 كيسًا/دقيقة (مقياس متوسط)

- FL20-3200: 180–300 كيس/دقيقة (على نطاق واسع)

- تنوع المنتجات - إذا كنت تتعامل مع أحجام متعددة، فابحث عن ميزات التغيير السريع مثل الأسطوانات القابلة للتبديل (φ12 مم - φ29 مم).

- تقلبات الطلبات – تتطلب الذروات الموسمية إنتاجية قابلة للتعديل دون فقدان الاستقرار.

1.3 المتطلبات الفنية

- دقة – يضمن التحكم المؤازر + المستشعرات الضوئية الكهربائية العد الدقيق والتعامل اللطيف.

- استقرار - ابحث عن الموثوقية المثبتة والمكونات عالية الجودة وميزات الصيانة الوقائية.

- الامتثال للنظافة - في الأغذية والأدوية ومستحضرات التجميل، اختر التصميمات المتوافقة مع ممارسات التصنيع الجيدة (GMP) ذات الأسطح سهلة التنظيف.

- القدرة على التكيف البيئي - ضمان الحماية من الحرارة والرطوبة والغبار حسب الحاجة.

1.4 المساحة والتركيب

- تحقق من أبعاد المعدات مقابل مخطط الطابق الخاص بك، مع ترك مساحة للتشغيل والصيانة والسلامة.

- تطابق الواجهات مع المعدات العلوية والسفلية (الارتفاع والعرض واتجاه التغذية).

- التحقق من الطاقة المتوفرة (4.7–8.7 كيلو واط حسب الطراز) وإمدادات الهواء.

الفصل الثاني: مقارنات النماذج

| نموذج | السرعة (أكياس/دقيقة) | نطاق الطول (مم) | بكرات | كمية المؤازرة | قوة | وزن | الأفضل ل |

|---|---|---|---|---|---|---|---|

| FL10-1800 | 80–120 | 85–168 | φ12 | 10 | 4.7 كيلو واط | 287 كجم | مضغوط، صغير الحجم |

| FL10-2800 | 80–120 | 145–290 | φ29 | 10 | 4.7 كيلو واط | 470 كجم | أكياس متوسطة الحجم |

| FL14-2900 (صغير) | 100–120 | 85–168 | φ12 | 14 | 6.2 كيلو واط | 570 كجم | أكياس صغيرة متوسطة الحجم |

| FL14-2900 (كبير) | 100–120 | 145–290 | φ29 | 14 | 6.2 كيلو واط | 650 كجم | أكياس متوسطة الحجم وكبيرة |

| FL20-3200 | 180–300 | 84–168 | φ12 | 20 | 8.7 كيلو واط | 820 كجم | خطوط واسعة النطاق وعالية السرعة |

الفصل الثالث: عملية الاختيار خطوة بخطوة

- البحث والتحليل - قم برسم خريطة لخط إنتاجك الحالي، وجمع مواصفات الكيس، وتوقع ما بين 3 إلى 5 سنوات قادمة.

- تحديد نقاط الألم - تحديد تكاليف العمالة، وحدود السرعة، وقضايا الجودة.

- تحديد الاحتياجات الفنية - تشمل متطلبات الأداء والتوافق والنظافة.

- تقييم الخيارات المتعددة - مقارنة القدرات التقنية والتكلفة وسهولة التكامل.

- التحقق من قوة المورد - مراجعة البحث والتطوير، وجودة التصنيع، وشبكة الخدمات، والمراجع.

- اختبار وتحقق - إجراء تجارب تجريبية على المنتجات الحقيقية قبل الانتهاء منها.

الفصل الرابع: دراسات الحالة

ترقية مصنعي الأغذية

- قديم: يدوي 25-30 كيس/دقيقة، 4 عمال، أخطاء 2-3%.

- جديد: FL14-2900، ١٠٠-١١٠ أكياس/دقيقة، مشغل واحد، أخطاء أقل من ٠.١١TP3T. عائد الاستثمار خلال ١٨ شهرًا.

الامتثال لممارسات التصنيع الجيدة (GMP) في مجال الأدوية

- التحدي: عدم التلوث، النظافة الصارمة، الدقة العالية.

- الحل: FL20-3200 مخصص مع الفولاذ المقاوم للصدأ 316L، وتصميم بدون زاوية ميتة، ووثائق التحقق الكاملة.

- النتيجة: زيادة السرعة بمقدار 10 مرات، واجتياز تدقيق GMP، والعائد على الاستثمار في 3 سنوات.

مرونة التعبئة والتغليف للتصدير

- التحدي: 8+ أحجام للمنتجات، والتغييرات المتكررة.

- الحل: FL14-2900 مع بكرات معيارية، وتغييرات في 30 دقيقة، وتبديل الوصفة بلمسة واحدة.

- النتيجة: كفاءة أعلى لـ 60%، وعدد أقل من المعدات.

الفصل الخامس: العائد على الاستثمار والتحكم في المخاطر

- الادخار المباشر - تخفيضات في تكاليف العمالة بمقدار 80% أو أكثر.

- مكاسب الإيرادات - إنتاج أسرع = تنفيذ المزيد من الطلبات.

- فوائد الجودة - انخفاض معدلات العيوب، وعدد أقل من الشكاوى.

- التحكم في المخاطر - اختر نماذج قابلة للتطوير والتحديث من الموردين الموثوقين.

الخاتمة وتوصيات الخبراء

اختيار الصحيح آلة عد الأكياس الأوتوماتيكية يتطلب مطابقة واقع الإنتاج الخاص بك مع التكوين الفني المناسب.

عوامل النجاح الرئيسية:

- تحليل شامل للاحتياجات

- الأداء المتوازن مقابل الميزانية

- دعم قوي للموردين

- تم التحقق من الموثوقية من خلال التجارب

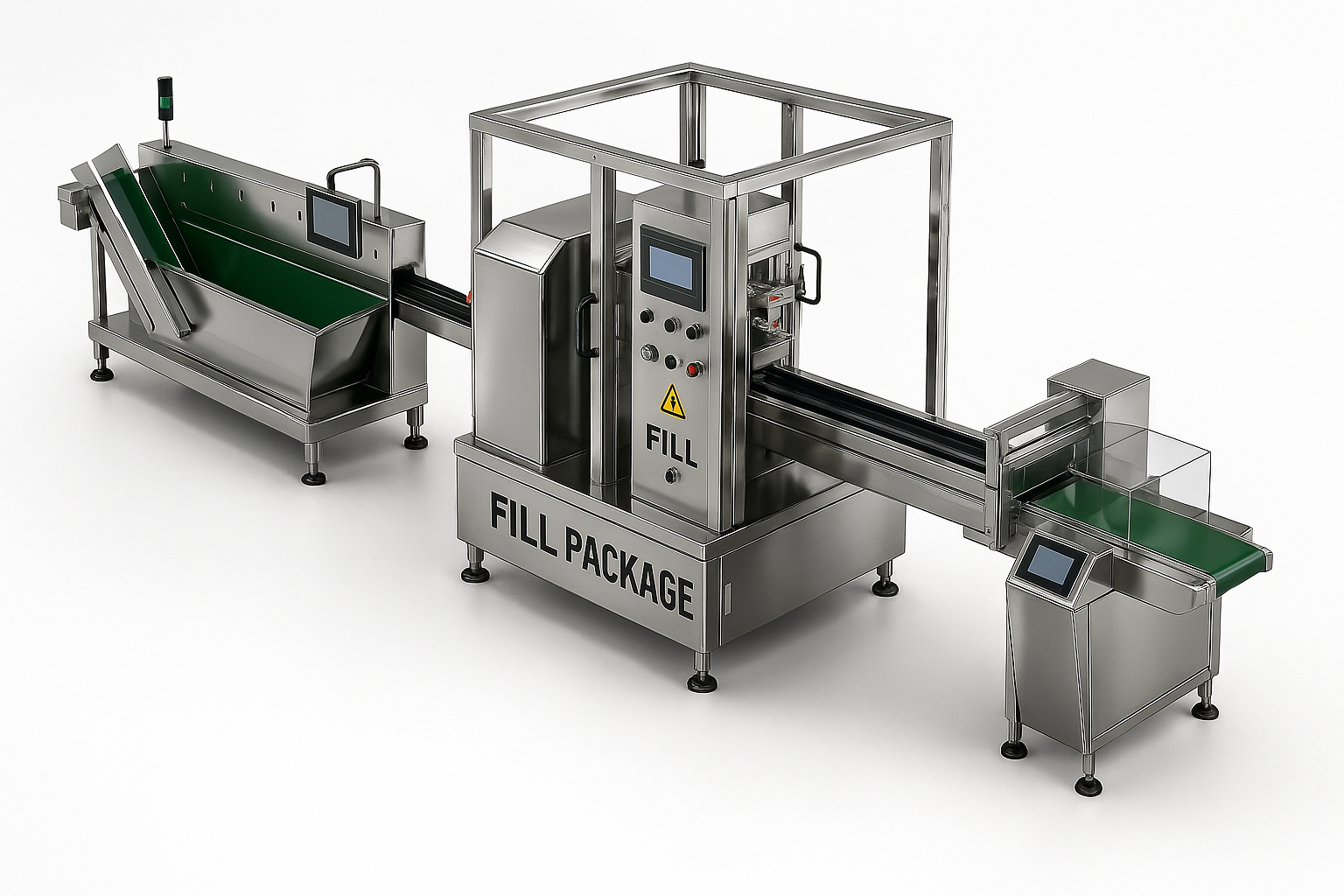

في Fillpackage، نحن نقدم استشارات فنية مجانية, اختبار العينة، و حلول مخصصة لضمان حصول استثمارك على أقصى قيمة.

اتصل بنا

- 🌐 www.fill-package.com

- 📧 [email protected]

- 📞 +86-13536680274