- دليل عملي لأداء التكلفة في معدات التعبئة والتغليف الأوتوماتيكية

عندما يتعلق الأمر بـ آلة التعبئة والتغليف الأوتوماتيكية في ظل الاختيار الصعب، يقف العديد من المشترين عند مفترق طرق بين الهيبة والعملية.

هل يجب عليك أن تختار الهندسة التي تم اختبارها عبر الزمن في ألمانيا أو اليابان أو الولايات المتحدة؟

أو هل يجب عليك أن تفكر في حل سريع التطور وفعال من حيث التكلفة؟ الشركة المصنعة لآلات التعبئة والتغليف الصينية?

لنكن صريحين - من حيث المواد الأساسية، والتصنيع الدقيق، ومنطق التحكم، والإرث الصناعي، لا تزال آلات التعبئة والتغليف من الدول المتقدمة تُمثل قمة العالم. علامات تجارية مثل إيشيدا قادرة على الوصول إلى أكثر من 180 عبوة في الدقيقة، مع تفاوتات جزئية تصل إلى ±0.01 مم، ذات جماليات جميلة، وعمر افتراضي طويل يصل إلى 10 سنوات أو أكثر.

ولكن عندما تتعامل مع المنتجات غير القياسيةإذا كنت تمتلك ميزانية محدودة، أو كنت تحتاج فقط إلى شيء ما لتشغيله بسرعة، فإن الأتمتة الصينية تعيد كتابة معادلة القيمة.

ما هي أفضل آلات التغليف الصينية؟

لا، ليسوا مثاليين. لكنهم جيدة بما يكفي لحل مشاكل التغليف في العالم الحقيقي - بأسعار معقولة، وبسرعة، وبمرونة.

✅ 1. تصميم الوظيفة أولاً

انسَ الأجراس والصفارات - تم تصميم معدات التغليف الصينية للعمل بكفاءة، وتقليل وقت التوقف، والتعامل مع التحديات الخاصة بالمنتج مثل الصلصات، أو العناصر غير المنتظمة، أو وحدات SKU متعددة الأحجام.

✅ 2. ميزة التكلفة: أقل بمقدار 40-60%

معيار ميزان متعدد الرؤوس من حزمة التعبئة تبدأ من $4,500، مقارنة بـ $80,000 أو أكثر لعلامة تجارية عالمية - وهذا أقل من نصف التكلفة مع 85% من الوظيفة.

✅ 3. أوقات تسليم سريعة، تخصيص سريع

الآلات القياسية: 10-30 يومًا

الآلات المخصصة: حتى 60-65 يومًا

تتطلب الآلات الغربية في كثير من الأحيان 14-18 أسبوعًا أو أطول.

✅ 4. خدمة ما بعد البيع سريعة - خاصة في آسيا

مع وكلاء Fill Package في جميع أنحاء جنوب شرق آسيا، يمكننا أن نقدم:

التشخيص عن بعد خلال 24 ساعة

دعم في الموقع في أقل من 72 ساعة

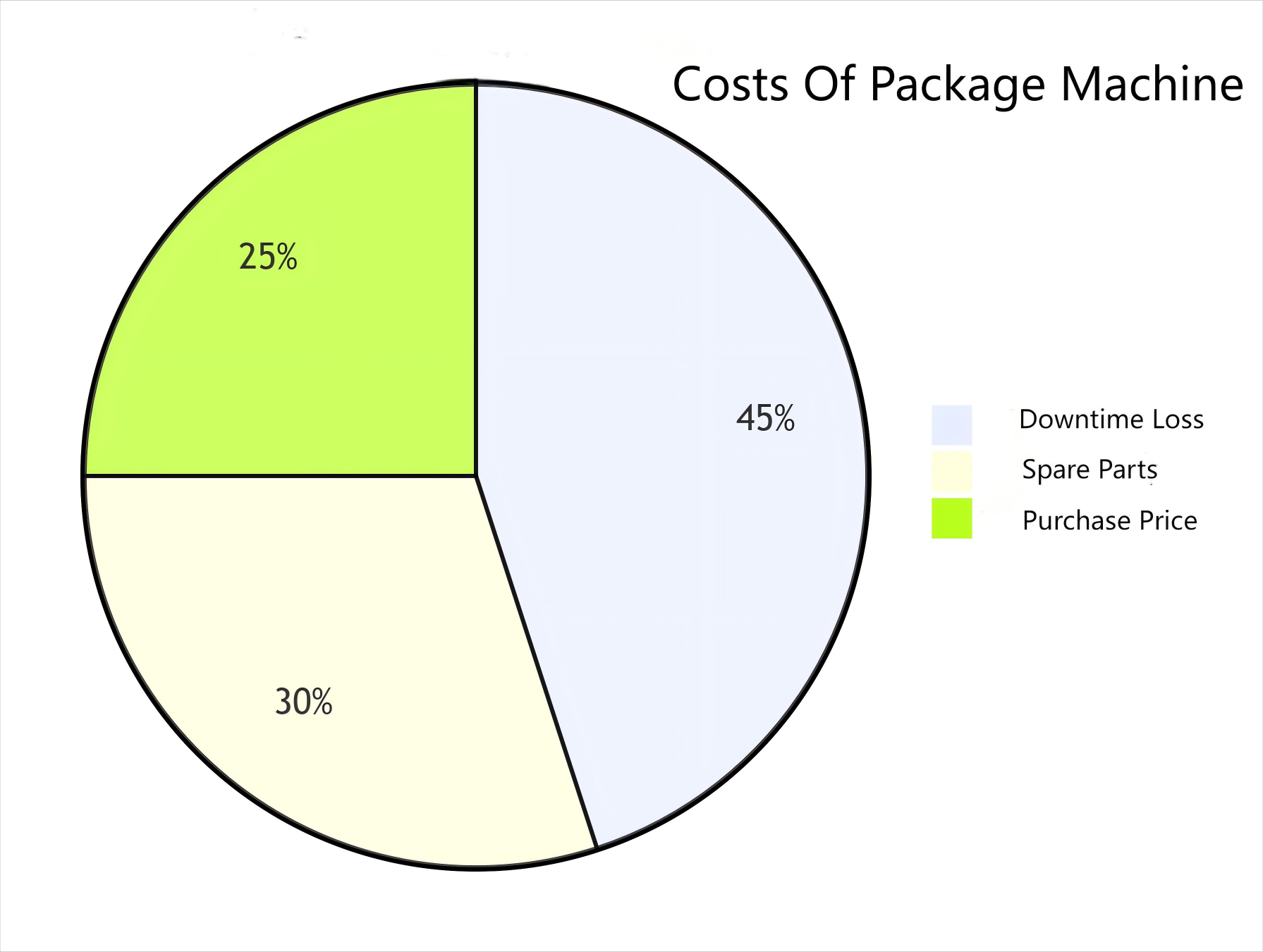

التحقق من واقع عائد الاستثمار: مقارنة التكاليف على مدى ثلاث سنوات

دعونا نأخذ مثالا حقيقيا - مقارنة 10 رؤوس ميزان متعدد الرؤوس أوتوماتيكي:

| فئة | علامة تجارية كبيرة | تعبئة الحزمة |

|---|---|---|

| سعر الشراء | $80,000 | $4,500 |

| قطع الغيار (3 سنوات) | $12,000 | $1,000 (السنة الأولى مجانية) |

| خسارة وقت التوقف* | $9,000/السنة × 3 = $27,000 | $3,000/السنة × 3 = $9,000 |

| التكلفة الإجمالية لمدة 3 سنوات | $119,000 | $14,500 |

*تقديرًا بـ $3,000/يومًا × 3 أيام/سنة لتوقف الإنتاج.

اسأل نفسك: هل ستنفق 1/10 من تكلفة 85% من الأداء و دعم على مستوى التأمين على مدار الساعة طوال أيام الأسبوع?

نحن نبني بمكونات متميزة - مصدرها عالمي

قد يكون مقرنا في الصين، لكننا نتبع معايير الجودة العالمية. إليكم نظرة على المكونات الأساسية منا معدات تغليف المواد الغذائية:

نظام التحكم

شاشة تعمل باللمس: WEINVIEW / تايوان

PLC: ميتسوبيشي / اليابان

محرك سيرفو: شنايدر / فرنسا

وحدة التحكم في درجة الحرارة: AESET / الصين

مستشعر ضوئي كهربائي: CNBDL / الصين

النيوماتيك

جميع الأسطوانات والصمامات: AirTAC / تايوان

الأجهزة الكهربائية

مرحلات: OMRON / اليابان

الحالة الصلبة: جيالي / سويسرا

السلامة والحركة

مستشعر القرب: FOTEK / تايوان

قاطع الدائرة: CHNT / الصين

الحزام: YONGLI أو Hongsbelt

المحركات: خياطة

الكلمة الأخيرة: ليس الأغلى، لكنه الأكثر ملاءمة

هناك مقولة تقول:

العلامة التجارية العالمية أشبه بشريك أحلام، ولكن ليس كل من يتزوج أحلامه. فالتوافق هو الأهم.

في أتمتة التعبئة والتغليف، أفضل استثمار هو الذي يوازن بين التكلفة والأداء والمرونة لمرحلتك الحالية - وليس فقط العلامة التجارية الموجودة على لوحة الاسم.

أخبرنا عن منتجك ومعاناتك - وسنعرض لك المنتج المناسب

فقط أخبرنا:

✅ ما هي تغليفاتكم؟ (مثلًا: رقائق البطاطس، شرائح المانجو، معجون الروبيان)

✅ تجربة التوقف الأكثر إيلامًا

✅ نطاق الميزانية

سوف نرسل لك:

🎁 تقرير توصية بالمعدات المخصصة

🎥 فيديو واقعي يحل مشكلتك بالضبط