مقدمة A high-speed multihead weigher needs a steady flow of material to work correctly. Many producers focus only on the weighing machine. However, the wrong conveyor can cause product fallback, sticking, or damage before the material even reaches the scale. At Fill Package, we design specialized أنظمة النقل to handle these difficult challenges.

Heading 2: Solve Product Fallback with Cleated Belt Conveyors When transporting materials at a steep angle, standard flat belts often fail. Sticky items like marinated meat or wet vegetables can slide backward.

The Cleated Design: ملكنا Cleated Belt Conveyors feature integrated dividers or “cleats”.

No More Sliding: These cleats act as tiny buckets, carrying sticky or loose items securely up the incline.

Explore Our Range: View our Cleated Belt Conveyor systems for high-incline feeding.

Heading 3: Protect Fragile Items with Gentle Bucket Elevators Fragile products like cannabis flowers, snacks, or ready-meal components require gentle handling.

Z-Type Motion: ملكنا Z-Bucket Elevators move materials horizontally and vertically without rough transitions.

Reduce Breakage: This design minimizes the impact on your product, preserving the visual appeal and quality of the items.

Check the Tech: Discover how our مصاعد من النوع Z protect your ROI.

Heading 4: Easy Sanitization for Food Safety Standards In food production, hygiene is just as important as speed.

المواد الصالحة للأكل: We use FDA-approved PU or PVC belts that are easy to clean and maintain.

Quick Washdown: Our conveyor frames support a full washdown, making them ideal for humid processing environments.

Heading 5: Bowl Conveyor: The Ultimate Leak-Proof Solution for Sticky Food Transport

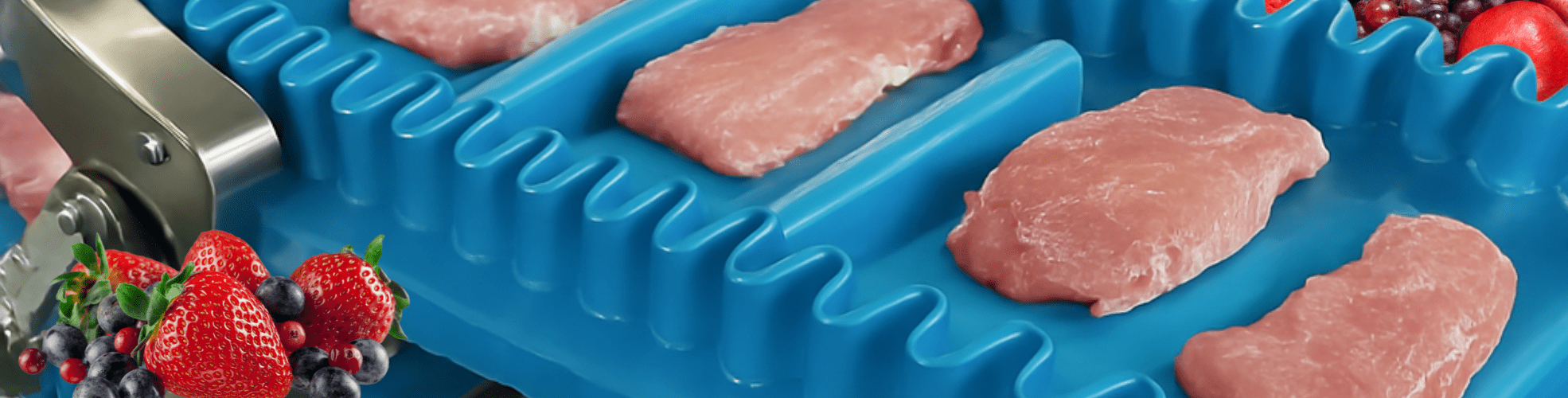

مقدمة Managing the transport of saucy and sticky materials often requires more than just a standard belt. Standard conveyors frequently lead to messy leaks or product fallback when handling marinated items. Consequently, we developed the ناقل وعاء من النوع Z to provide a fully enclosed and hygienic lifting solution.

Heading 5..: Why Choose a Bowl Conveyor for Your Ready Meal Line? Traditional vibration feeders often struggle with wet materials like kimchi or saucy meats. In contrast, our bowl elevator offers several key advantages for these difficult products:

Leak-Proof Performance: Each food-grade ABS or PP bowl acts as a sealed container. وهذا يضمن that expensive sauces and juices remain with the product instead of leaking onto the floor.

تصميم موفر للمساحة: The Z-type configuration allows you to move products both horizontally and vertically. Additionally, this compact footprint is ideal for factories with low ceilings or limited floor space.

Gentle Material Handling: Because the product sits statically inside the bowl during the lift, there is no friction or breakage. Moreover, this preserves the visual quality of delicate items like marinated poultry or seafood.

Heading 5.3: Simplified Cleaning and High Hygiene Standards Hygiene is a top priority in food packaging. For this reason, we designed our bowl conveyors with tool-free maintenance in mind.

Detachable Bowls: Operators can quickly remove individual bowls for deep cleaning between different batches. As a result, you can significantly reduce downtime during product changeovers.

Waterproof Construction: The system supports high-pressure washdowns, which is vital for meat processing environments.

خاتمة The right transport system is just as important as the weigher itself. By integrating our Bowl Conveyor with a وحدة تغذية لولبية, you create a complete, high-efficiency line for sticky products.