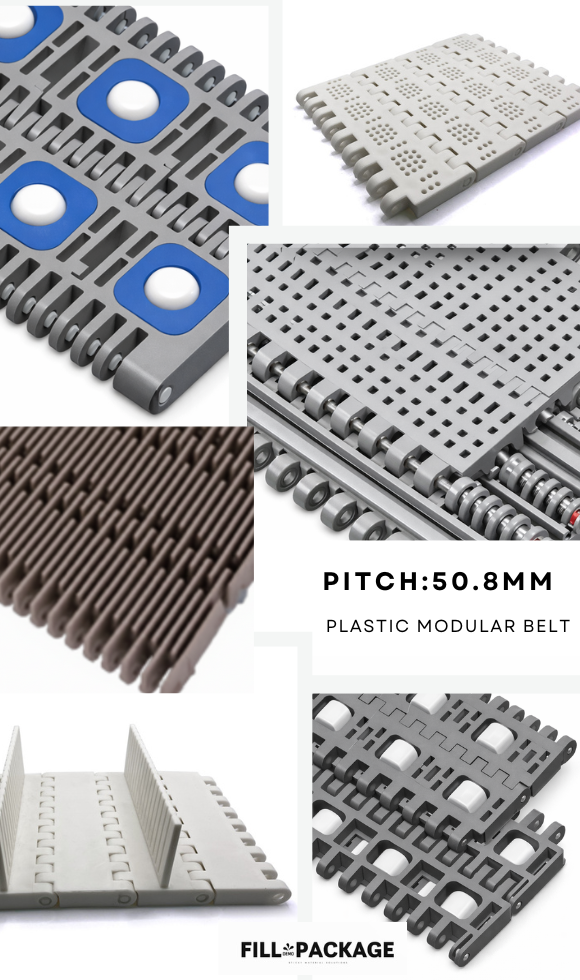

Large Pitch Modular Belt (2-Inch Series, 50.8 mm)

Engineered for maximum strength and durability, the large pitch modular belt is the definitive solution for heavy-duty conveying. While the large pitch category spans from 27.2mm to 62.5mm, the 2-inch (50.8 mm) series stands as the flagship, offering the most comprehensive range of solutions for demanding industrial environments.

Introduction: The Foundation of Heavy-Duty Conveying

What Is a Large Pitch Modular Belt?

A large pitch modular belt is defined by its significant distance between hinge points, typically ranging from 27.2mm up to 62.5mm. This increased pitch results in a fundamentally different structure compared to standard or small pitch belts. The larger dimensions allow for thicker, more robust module construction and heavier-duty hinge designs. This is why a larger pitch directly translates to a stronger, more resilient belt. The design of أ modular belt 50.8 mm pitch inherently provides the structural reinforcement needed for industrial conveying.

The 2-Inch (50.8mm) Series: The Flagship of Large Pitch Belts

Key Features of the 2-Inch Modular Belt Series

- Unmatched Load Capacity: With working loads ranging from 12,500 N to an industry-leading 73,000 N, this series can handle the most demanding applications.

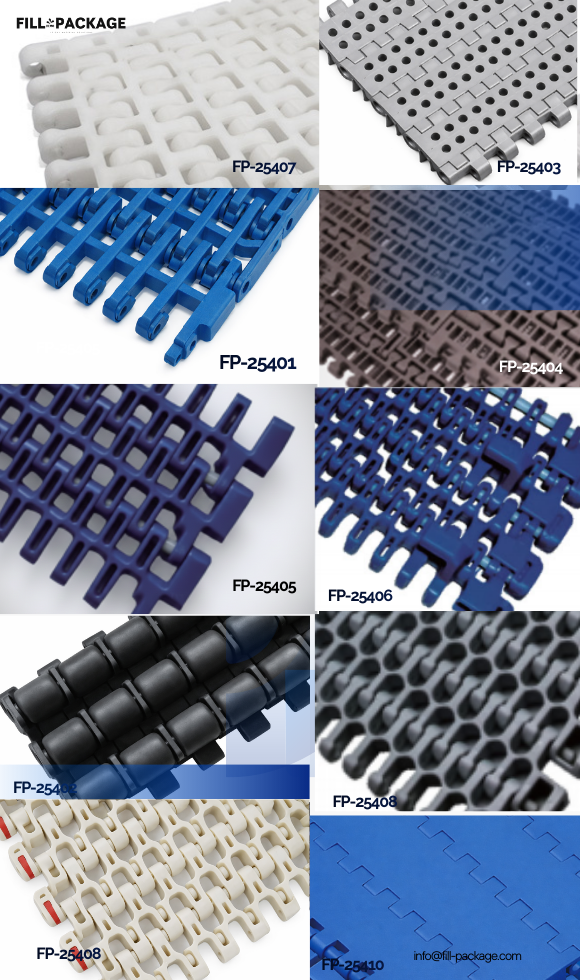

- Exceptional Versatility: The 2-inch series includes a wide variety of surface types, including:

- Flat Grid & Flat Top: For general-purpose heavy conveying.

- Ball & Roller Top: For low-friction accumulation and multidirectional movement.

- Rib & Convex Top: For enhanced grip on inclined or wet surfaces.

- Turning Belts: For curved and spiral conveyor systems.

- Robust Modular Construction: Thicker modules and larger rod diameters (up to 8mm) ensure maximum strength and impact resistance.

- Stable Conveying for Heavy Products: The wide, flat surface provides a stable platform for items like large boxes, containers, and fully packed cases.

Other Large Pitch Options

- 27.2mm & 31.75mm: For medium-to-heavy loads where a slightly smaller pitch is beneficial.

- 38.1mm (1.5-inch): A highly versatile series with numerous turning and flat top options.

- 40mm, 46mm, 50mm: Specialized pitches for unique application requirements.

- 55.6mm, 57.15mm, 62.5mm: For ultra-heavy-duty or specialized industrial conveying.

التطبيقات النموذجية

- Cartons and Cases Conveying: Ideal for end-of-line packaging, warehousing, and distribution, where heavy, sealed cartons need to be moved reliably.

- Boxed Products in Packaging Lines: A core component in large pitch modular belt for packaging lines, handling everything from beverage cases to bulk food containers.

- Industrial Goods and Containers: Transporting automotive parts, building materials, or large plastic totes in a manufacturing environment.

- Heavy Finished Packages: Moving fully assembled and packaged goods from the production floor to the shipping dock.

Large Pitch vs. Standard Pitch Modular Belts

ميزة | Large Pitch Modular Belt (2-Inch) | Standard Pitch Modular Belt (1-Inch) |

سعة التحميل | Very High (up to 73,000 N) | متوسطة إلى عالية |

الاستخدام الأساسي | Heavy, large, bulk items | General purpose, medium-sized items |

استقرار | Excellent for heavy loads | Good for a wide range of products |

التنوع | Specialized for heavy-duty | Highly versatile, many variants |

Cost & Maintenance | Higher initial cost, lower maintenance under heavy load | Lower initial cost, may require more maintenance if overloaded |

Integration with Packaging and Conveying Equipment

- خطوط التعبئة والتغليف: As the primary mover for case packers, sealers, and palletizers.

- Transfer Conveyors: Reliably moving heavy products between different stages of production or warehousing.

- Accumulation and Discharge Sections: Withstanding the high pressure and weight of products accumulating before sorting or shipping.

Why Choose a Large Pitch Modular Belt?

Opting for a large pitch belt is a strategic decision for long-term operational efficiency and reliability.

- Heavy-Duty Performance: It is the only choice for applications that exceed the load limits of smaller pitch belts.

- Long Service Life: The robust design leads to less wear and tear, even under constant, heavy use, resulting in a longer operational lifespan.

- صيانة منخفضة: Fewer breakdowns and less need for replacement parts mean lower total cost of ownership, especially in high-throughput environments.

- Industrial-Grade Reliability: Provides the peace of mind that your conveyor system can handle the toughest jobs without failure.

منتج ذو صلة

Explore Our Large Pitch Modular Belt Solutions

Ready to build a conveyor system that can handle any challenge? Our heavy duty modular belt applications are designed to meet the most demanding industrial needs. Contact our engineering team today to discuss your specific requirements, confirm specifications, and find the perfect high load modular conveyor belt for your facility. Let us help you build a system that is stronger, more reliable, and built to last.

أ large pitch modular belt is defined by its increased distance between hinge points, typically ranging from 27.2mm to 62.5mm, with the 2-inch (50.8mm) series being the most common. In contrast, a standard pitch modular belt has a 1-inch (25.4mm) pitch. The larger pitch translates directly into a stronger, more robust structure. Modules are thicker, rods are larger in diameter, and the overall belt can support significantly higher loads. While standard pitch belts are ideal for general-purpose conveying, large pitch belts are specifically engineered for التطبيقات الشاقة where load capacity and durability are paramount.

- Heavy products: Items such as large cartons, cases, industrial containers, or bulk packages that exceed the load limits of standard pitch belts.

- High-load requirements: Applications requiring working loads above 35,000 N, which standard pitch belts cannot reliably support.

- Rugged environments: Manufacturing or distribution settings where the belt must withstand constant heavy use, impacts, or abrasive conditions.

- Long service life priority: Situations where minimizing downtime and replacement frequency is critical to operational efficiency.

- FP-50803 Flat Grid Chain (POM/PA): 73,000 N

- FP-50804Z Directional Ball Net Chain (POM/PA): 48,000 N

- FP-50809W Turning Net Chain (POM/PA): 26,000 N

Yes, specific large pitch modular belts are designed for curved and spiral conveyor systems. The FP-50809 series (Turning Net Chain) within the 2-inch (50.8mm) family is engineered to handle turns while maintaining high load capacity. Additionally, the 38.1mm (1.5-inch) series offers multiple turning belt options, such as the FP-38103W and FP-38104W series. These belts feature specialized module designs that allow for smooth, reliable operation on curved tracks, making them ideal for complex conveyor layouts in packaging and distribution facilities.

- POM/PA (Polyoxymethylene / Polyamide): Offers the highest strength and load capacity. Ideal for heavy-duty industrial applications. Temperature range: -40°C to +90°C.

- PP/PA (Polypropylene / Polyamide): Provides excellent chemical resistance and is FDA-approved for food contact. Suitable for food processing and packaging. Temperature range: -10°C to +80°C.

- PP/PP (Polypropylene / Polypropylene): Cost-effective option for moderate loads in dry environments.

- PE/PE (Polyethylene / Polyethylene): Lightweight and economical, best for lighter-duty applications within the large pitch category.

- PA/PA (Polyamide / Polyamide): High wear resistance and good temperature tolerance.

Yes, many large pitch modular belts are suitable for food processing and packaging, provided they are made from FDA-approved materials such as PP (Polypropylene) or PE (Polyethylene). The 2-inch (50.8mm) series includes numerous variants with open grid or perforated designs, which facilitate excellent drainage and easy cleaning—critical features for maintaining hygiene standards. Belts with higher open areas (e.g., 30%-46%) allow liquids and debris to pass through, preventing buildup and simplifying sanitation. Always confirm material certifications and cleaning protocols with your supplier to ensure compliance with food safety regulations.

- Product width + 50-100mm clearance: Ensure the belt is wider than your product to prevent tipping or jamming.

- Accumulation zones: Wider belts provide more stability for products that may accumulate or queue.

- Standard widths: Large pitch modular belts are available in a variety of standard widths, typically ranging from 30mm to over 300mm, depending on the series.

- Flat Top / Flat Grid: Provides a smooth, stable surface for general heavy-duty conveying. Ideal for cartons, cases, and boxed products. Open grid designs offer drainage and easy cleaning.

- Ball Top / Roller Top: Features embedded rollers or balls that reduce friction, allowing products to move easily in multiple directions. Perfect for accumulation zones, merging, and diverting applications in logistics and distribution.

- Rib Top / Convex Top: Incorporates raised ribs or convex patterns to increase grip and prevent slippage, especially on inclined conveyors or in wet environments.

- Regular Inspection: Check for worn modules, damaged rods, or misaligned sprockets at least monthly.

- تنظيف: Remove debris and buildup regularly. For food applications, follow sanitation protocols and use approved cleaning agents.

- تشحيم: Most modular belts are designed to run dry, but check manufacturer recommendations. If lubrication is required, use food-grade lubricants for food contact applications.

- ضبط التوتر: Maintain proper belt tension to prevent sagging or excessive wear. Adjust tensioning devices as needed.

- Module Replacement: Damaged modules can be replaced individually without removing the entire belt, minimizing downtime.

Yes, one of the key advantages of modular belt design is the ability to replace individual modules without removing the entire belt from the conveyor. If a module is damaged due to impact, wear, or other factors, you can simply remove the connecting rod, replace the damaged module, and reinsert the rod. This modular repair capability minimizes downtime and reduces maintenance costs, making large pitch modular belts a highly practical choice for high-throughput operations.

If you have additional questions or need assistance selecting the right heavy duty modular belt for your application, our engineering team is here to help. Contact us today to discuss your project requirements, confirm specifications, and receive a detailed quote.