What is a Photoelectric Sensor?

Обзор продукта

How Does a Photoelectric Sensor Work?

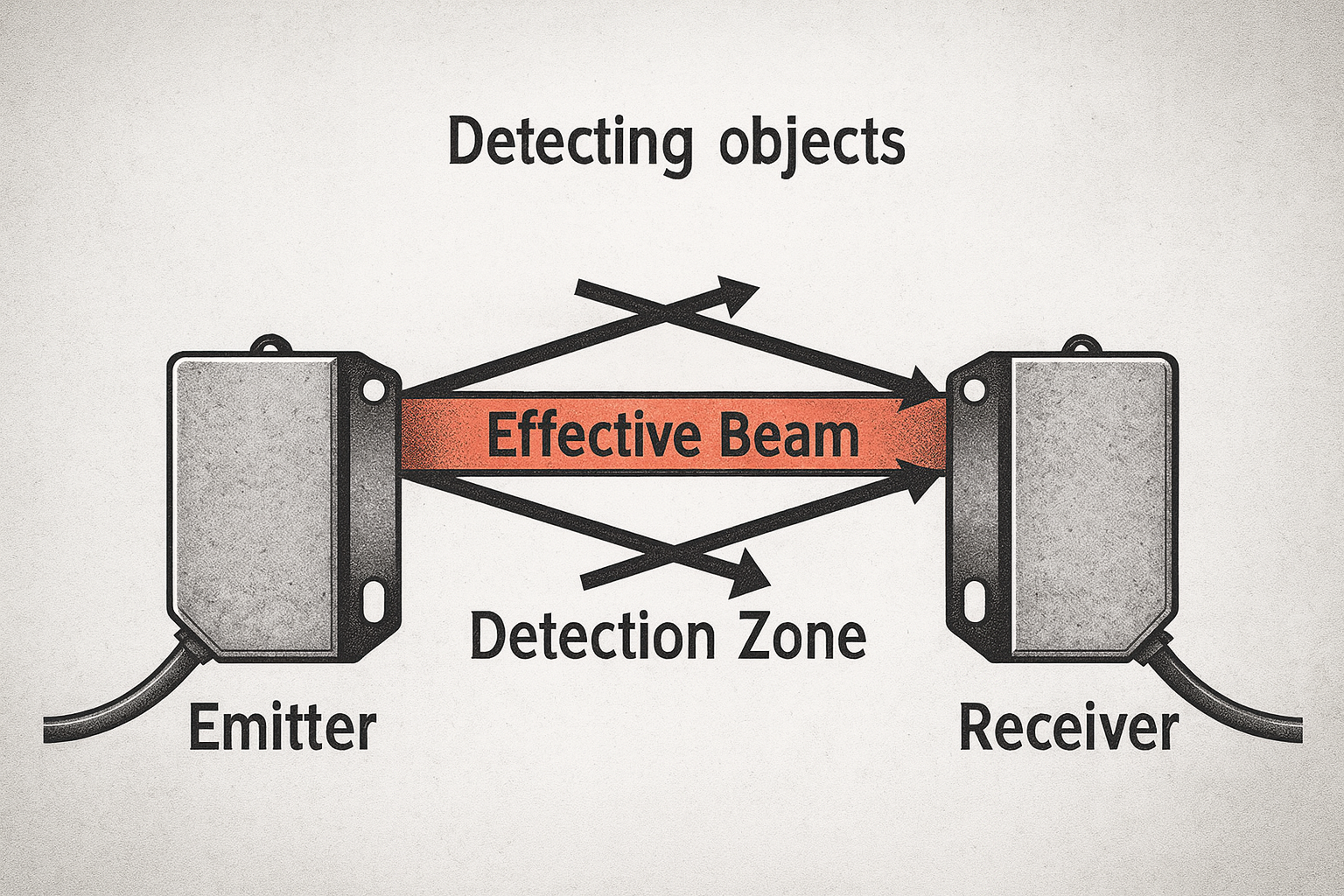

A photoelectric sensor operates on the principle of light beam interruption or reflection. Here’s how it works:

- Emitter sends a beam of infrared or visible light.

- Receiver detects the beam.

- When an object interrupts or reflects the beam, the sensor detects a change in light.

- The sensor then triggers an electrical signal to the control system (PLC or controller).

Types of Photoelectric Sensors:

| Тип | Описание | Вариант использования |

|---|---|---|

| Through-Beam (Opposed) | Emitter and receiver are separate; beam is blocked by the target | Long distances, high reliability |

| Retroreflective | Emitter and receiver in one housing; uses reflector | Easy setup, general object detection |

| Diffuse Reflective | Light reflects directly off the object to the receiver | Short-range detection, transparent objects |

Key Features and Specifications

| Спецификация | Typical Value |

| Sensor Type | Through-beam Photoelectric Sensor |

| Detection Range | Up to 20+ meters |

| Light Source | Infrared LED (940nm) |

| Supply Voltage | 10-30 VDC |

| Response Time | < 1ms |

| Output Type | PNP/NPN (selectable) |

| Protection Rating | IP67 |

| Рабочая температура | -30°C to +60°C |

| Housing Material | Metal (brass/stainless steel) |

| Connection | Cable or connector options |

Applications of Photoelectric Sensors

Photoelectric sensors are essential in modern промышленная автоматизация due to their speed and versatility.

Industrial Automation

- Detecting parts on assembly lines

- Positioning and alignment

- Presence/absence sensing

Photo Eye Sensor for Conveyor

- Detect packages on moving belts

- Trigger diverters and sorters

- Count products in real time

Packaging & Labeling Systems

- Verify presence of labels

- Detect transparent or irregular-shaped packaging

- Trigger label application mechanisms

Food, Beverage & Pharmaceuticals

- Hygienic non-contact sensing

- Detect bottle fill levels

- Identify caps, seals, or missing components

Safety & Security

- Create optical safety barriers

- Monitor entry/exit points in restricted zones

Advantages of Photoelectric Sensors

1. Non-Contact Detection

•No physical wear or mechanical failure

2. High Precision and Speed

•Microsecond response times for high-speed applications

•Wide range of detectable materials and surfaces

4. Cost-Effective Solution

•Lower total cost of ownership compared to alternatives

Maintenance Tips for Long-Term Performance

- Clean lenses regularly with a soft cloth.

- Check alignment, especially in through-beam sensors.

- Avoid mounting sensors near high-vibration areas.

- Use protective covers in dusty or oily environments.

- Periodically test sensor output in system diagnostics.

Photoelectric Sensor Selection Guide

| Приложение | Recommended Type | Key Feature |

|---|---|---|

| Conveyor belt detection | Through-beam | Long range & precise alignment |

| Packaging line | Retroreflective | Easy to install with reflector |

| Transparent object detection | Diffuse with background suppression | High sensitivity |

| Harsh environments | IP67-rated sensors | Waterproof and dustproof |

| High-speed sorting | Fast-response sensor (<0.5ms) | Suitable for rapid detection |

- Product Summary

Photoelectric sensors are the smart choice for any industry looking to enhance automation, improve detection reliability, and minimize mechanical wear. Whether you’re working with conveyors, labeling machines, robotic arms, or packaging lines, these sensors deliver precision, скорость, и durability.

With a wide range of sensing distances and types available, choosing the right photo eye sensor has never been easier. Ensure operational excellence with high-quality photoelectric sensing technology.

Сопутствующий продукт

Ready to integrate фотоэлектрические датчики into your system?

Contact us now for a custom quote, bulk pricing, or help choosing the right sensor for your application.

📧 Электронная почта: info@fill-package.com

📞 Телефон: +8613536680274

🌐 Веб-сайт: www.fill-package.com

Photoelectric sensors are used to detect the presence, absence, or distance of objects using light beams. They’re commonly found in automation, conveyors, and packaging lines.

They emit a beam of light and detect objects when the beam is interrupted or reflected to the receiver.

Three main types: Through-beam, Retroreflective, and Diffuse Reflective.

A photo eye sensor detects items moving along the conveyor, triggering sorting or counting functions in automation systems.

Non-contact detection, fast response, high precision, and long sensing distances.

Affected by dirt, requires alignment, and can be sensitive to reflective surfaces or ambient light.

Yes, especially diffuse sensors with background suppression or specialized models.

Most sensors are plug-and-play, but sensitivity and alignment may need adjustment depending on the application.