Тестирование наполнения и упаковки

🛠️ Как мы проверяем и тестируем наше упаковочное оборудование

– Настоящие машины. Настоящие испытания. Настоящая уверенность.

В Fill Package мы не верим в сюрпризы, особенно для наших клиентов.

Каждая поставляемая нами упаковочная машина прошла проверку многоэтапный процесс тестирования и проверки реального продукта что гарантирует надежность, точность и готовность вашей системы к производству еще до того, как она покинет наш цех.

Вот как мы гарантируем, что каждая машина соответствует вашим ожиданиям — функционально, структурно и эксплуатационным.

✅ Шаг 1: Тестирование начинается до того, как вы разместите заказ

Когда клиент проявляет серьезный интерес к нашему решению, мы не просто приводим спецификации — мы проводим тестирование реальные продукты или максимально близкие заменителиПоскольку материальные различия между странами (например, текстура мяса, размер закусок) могут влиять на производительность, мы проводим тестирование с использованием аналогичных товаров, доступных в Китае.

Этот предварительный тест предназначен для:

-

Смоделируйте ваше реальное приложение

-

Оцените поведение машины с учетом типа вашего продукта

-

Определите, требуется ли индивидуальная разработка

Только после того, как заказчик подтвердит удовлетворенность предварительными результатами испытаний, мы приступаем к официальному производству.

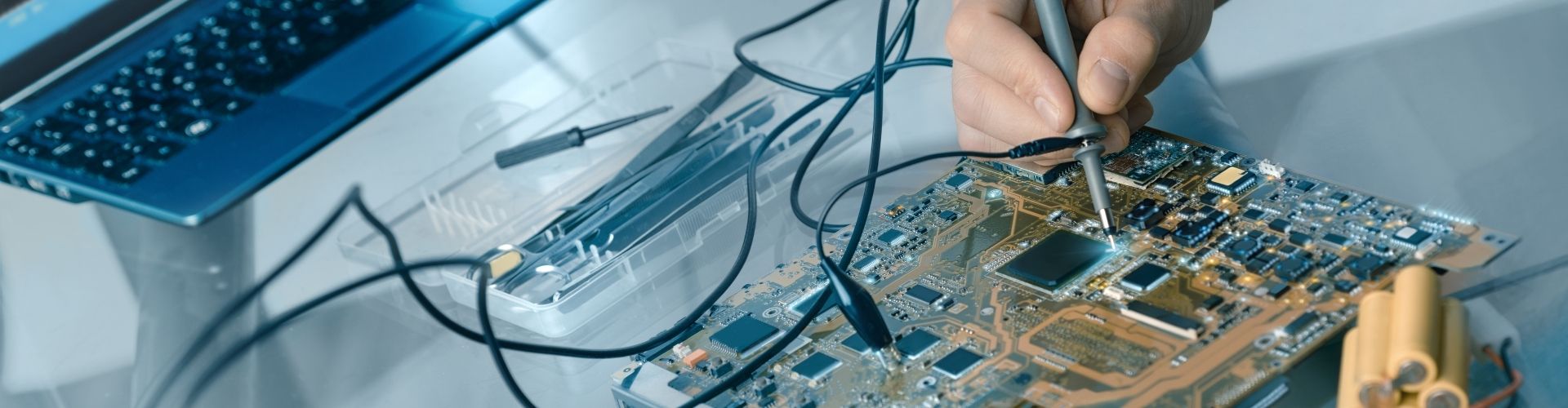

✅ Шаг 2: Точное производство + встроенный контроль качества

После подтверждения заказа наша инженерная группа окончательно определяет технические характеристики машины и приступает к изготовлению.

В процессе производства:

-

Встроенные инспекторы качества постоянный контроль сборки компонентов

-

Проверяется выравнивание конструкции, качество сварки, точность деталей и разводка проводов.

-

Любые отклонения от спецификации приводят к немедленным корректировкам.без утверждения процесса серийное производство не допускается

Мы рассматриваем контроль качества как непрерывный процесс, а не просто как конечную контрольную точку.

✅ Шаг 3: Окончательное тестирование продукта — имитация реального использования

После завершения сборки мы моделируем реальное производство, используя те же (или эквивалентные) продукты из Шага 1:

-

Машина полностью параметризована и настроена в соответствии с желаемыми настройками заказчика.

-

Эксплуатационные испытания проводятся для полных циклов, проверяя скорость выхода, вес наполнения, запечатывание пакетов, точность сортировки и т. д.

-

Видеодоказательства и отчеты о производительности предоставляются заказчику для подтверждения.

Если что-то выходит за рамки требуемого заказчиком диапазона, мы перенастроить и перепроверить прежде чем двигаться дальше.

✅ Шаг 4: 72-часовой тест на выгорание

После прохождения окончательного функционального испытания машина проходит 72-часовой непрерывный тест на старение (3 дня x 24 часа).

В этот период:

-

Оборудование работает без остановок под реальными или имитированными нагрузками.

-

Мы отслеживаем температуру двигателя, вибрацию, стабильность сигнала и надежность программного обеспечения.

-

Любые нарушения, задержки или неисправности отмечаются и устраняются перед выпуском.

Испытание на отказ обеспечивает долговременную надежность и предотвращает преждевременный отказ из-за скрытых дефектов.

✅ Шаг 5: Окончательный контроль качества — проверка внешнего вида, электрооборудования и безопасности

Перед упаковкой каждая машина проходит окончательную проверку, в ходе которой особое внимание уделяется:

-

Появление: Чистота, гладкость сварки, маркировка панелей, отделка поверхности

-

Электрические испытания: Совместимость напряжения и частоты с регионом заказчика (например, 220 В/60 Гц)

-

Проверка безопасности: Правильное заземление, установка предохранителей, изоляция проводки и функция аварийной остановки

Только после того, как все детали соответствуют нашему контрольному списку, мы приступаем к надежной упаковке и отправке.

🔧 А как насчет покупных компонентов?

Хотя в этой статье основное внимание уделяется тестированию всей машины, стоит отметить, что В Fill Package используются компоненты только от проверенных поставщиков., многие из которых всемирно признанные бренды. Мы проверяем поступающие двигатели, датчики, переключатели и ПЛК перед использованием и обеспечиваем отслеживаемость запасных частей на случай необходимости их замены в будущем.

💡 Почему это важно для вас

-

Нулевой риск несоответствия: Вы видите видеоролики испытаний машин с использованием продуктов, которые максимально соответствуют вашим собственным, еще до того, как мы их отправим.

-

Душевное спокойствие: Испытания на отказ и контроль качества устраняют «скрытые ошибки», которые часто проявляются после поставки.

-

Более быстрый ввод в эксплуатацию: Машины поставляются с заранее заданными параметрами, которые вы уже подтвердили.

-

Лучшая долгосрочная окупаемость инвестиций: Качество на начальном этапе означает меньше поломок, меньше технического обслуживания и более длительный срок службы оборудования.

🎬 Заключение

Машина настолько хороша, насколько хороши ее испытания.

В Fill Package мы считаем, что инспекция — это не шаг, а образ мышления. От первого теста до последнего болта, каждая часть нашего процесса построена так, чтобы гарантировать вы получаете машину, которая работает, служит долго и обеспечивает результаты с первого дня.

Хотите узнать, как ваш продукт будет работать на нашем оборудовании?