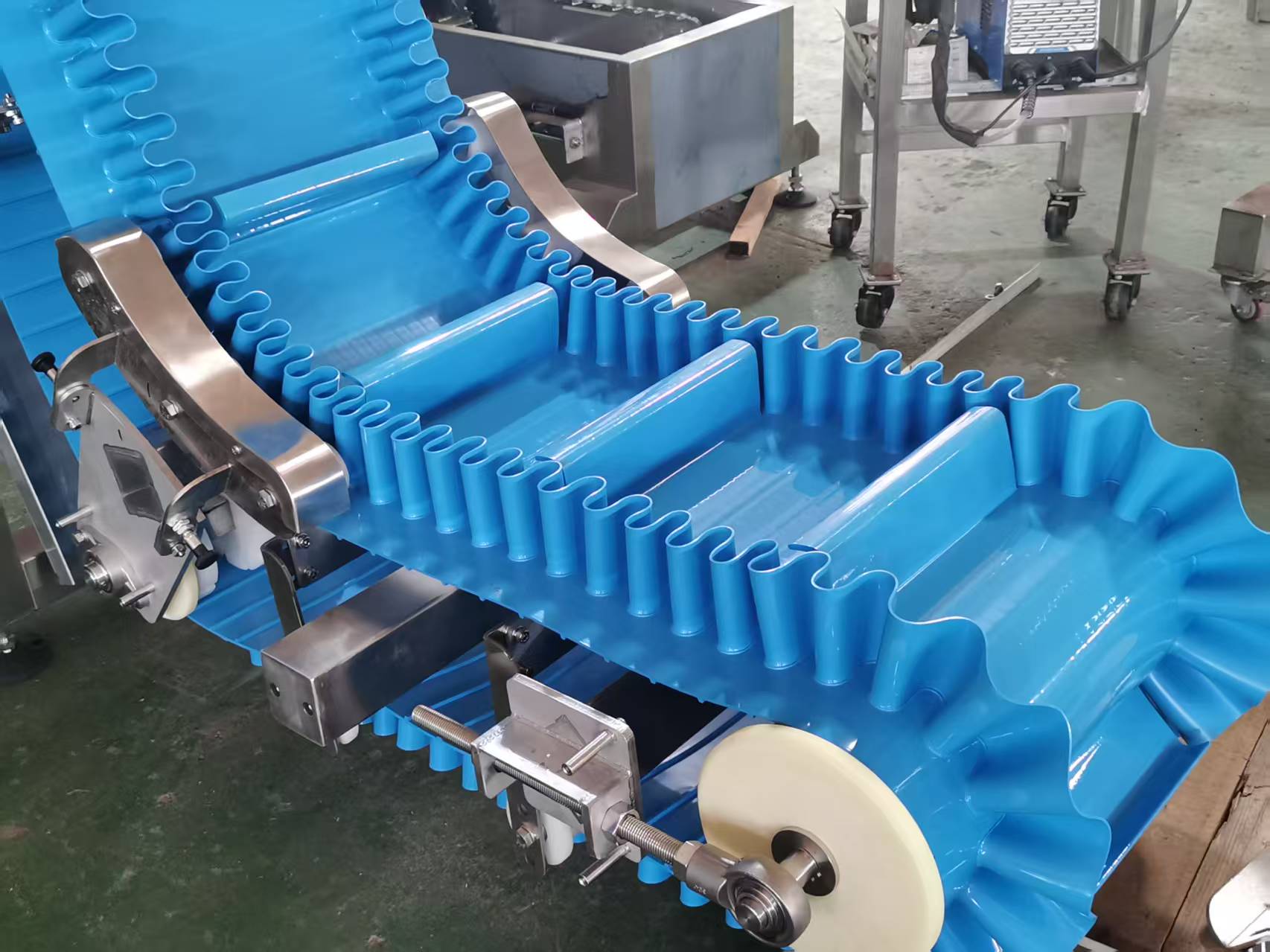

मांस प्रसंस्करण उद्योग में, कन्वेयर बेल्ट उत्पादन लाइनों का एक अनिवार्य घटक हैं, जो विभिन्न प्रसंस्करण चरणों में उत्पादों के कुशल परिवहन को सुगम बनाते हैं। फिर भी, उनकी स्वच्छता और सफाई बनाए रखना एक सतत चुनौती बनी हुई है। स्वच्छता की प्रभावशीलता न केवल परिचालन दक्षता को प्रभावित करती है, बल्कि खाद्य सुरक्षा मानकों पर भी गंभीर प्रभाव डालती है। यह लेख मांस प्रसंस्करण में कन्वेयर बेल्ट के लिए वर्तमान स्वच्छता प्रथाओं पर गहराई से चर्चा करता है, नवीन समाधानों पर प्रकाश डालता है, और सफाई के समय को महत्वपूर्ण रूप से कम करने के व्यावहारिक तरीके साझा करता है।

वर्तमान स्थिति और अपेक्षाएँ

आजकल, मांस प्रसंस्करण संयंत्रों में कन्वेयर बेल्ट की सफाई के लिए आमतौर पर गहन प्रयास और काफी समय की आवश्यकता होती है। उद्योग मानकों के अनुसार, कन्वेयर बेल्ट को दिन में कई बार सफाई, धुलाई और सैनिटाइजेशन की आवश्यकता हो सकती है, और प्रत्येक सत्र कई घंटों तक चलता है। बड़े पैमाने के मांस प्रसंस्करण संयंत्र अक्सर बेल्ट की पूरी तरह से सफाई और स्प्लिसिंग रखरखाव के लिए साल में कई बार 24 घंटे तक का समय देते हैं।

हालांकि, उत्पादन क्षमता को अधिकतम करने का लक्ष्य रखने वाले व्यवसायों के लिए, डाउनटाइम सीधे मुनाफे में कमी का कारण बनता है। कंपनियाँ लगातार "अपटाइम को अधिकतम करने और सफाई अंतराल को न्यूनतम करने" का प्रयास करती हैं, यह जानते हुए कि उत्पादन समय में वृद्धि सीधे लाभप्रदता को बढ़ाती है। सफल केस स्टडीज़ दर्शाती हैं कि नवीन सफाई विधियाँ सफाई के समय को 50% तक कम कर सकती हैं, जो उद्योग में सार्वभौमिक रूप से वांछित लक्ष्य है।

कन्वेयर बेल्ट स्वच्छता में अग्रणी कंपनियां और समाधान

विश्व स्तर पर, कई कंपनियां मांस प्रसंस्करण उद्योग के लिए विशेष रूप से तैयार किए गए अग्रणी स्वच्छता समाधान प्रदान करती हैं:

- फ्लेक्सको: कन्वेयर बेल्ट जोड़ने और रखरखाव में विशेषज्ञता, नोवीटूल® अमीगो™ प्रेस जैसे समाधान प्रदान करता है, जो स्वच्छता और स्प्लिसिंग समय को काफी कम कर देता है।

- इंट्रालॉक्स: मॉड्यूलर प्लास्टिक कन्वेयर बेल्ट के लिए प्रसिद्ध, उनके थर्मोड्राइव समाधान ने सैल्मन प्रसंस्करण अनुप्रयोगों में सफाई के समय को 50% तक उल्लेखनीय रूप से कम कर दिया। थर्मोड्राइव बेल्ट में सीमलेस, तनावरहित डिज़ाइन होते हैं, जो उन दरारों और अंतरालों को दूर करते हैं जहाँ बैक्टीरिया पनप सकते हैं।

- हबासित: एचएसीसीपी मानकों के अनुरूप खाद्य-ग्रेड कन्वेयर बेल्ट प्रदान करता है, जो स्वच्छता, दक्षता और कम डाउनटाइम पर ज़ोर देता है। उनकी सुपर हाइक्लीन® श्रृंखला समतल सतह और न्यूनतम कब्ज़े और पिन प्रदान करती है, जिससे सफाई आसान हो जाती है और संदूषण का जोखिम कम होता है।

- फोर्बो: मांस और पोल्ट्री प्रसंस्करण के लिए विशेष रूप से डिजाइन किए गए सीगलिंग ट्रांसिलॉन ईजी क्लीन बेल्ट विकसित किए गए हैं, जो कड़े स्वच्छता मानकों का पालन करते हैं।

- सीपेक्स: EHEDG और US 3A स्वच्छता मानकों को पूरा करने वाले पंप प्रदान करता है, जो प्रभावी क्लीन-इन-प्लेस (CIP) प्रणालियों का समर्थन करता है।

- नोबललाइट: स्टेरिबेल्ट यूवी प्रणाली, एक प्रभावी पराबैंगनी स्वच्छता समाधान प्रदान करता है जो बेहतर स्वच्छता के लिए सीधे कन्वेयर बेल्ट सतहों को लक्षित करता है।

- वूशी **** कन्वेयर बेल्ट कंपनी: लगातार उच्च तापमान धुलाई और स्वच्छता उपचार के लिए उपयुक्त चिकनी सतह बेल्ट की आपूर्ति करता है।

- गुआंगज़ौ ****: त्वरित स्वच्छता के लिए सहज डिजाइन वाली, आसानी से साफ होने वाली, रसायन प्रतिरोधी सफेद पीयू खाद्य ग्रेड कन्वेयर बेल्ट का नवाचार किया गया है।

- पैकेज भरें सटीक उद्योग कन्वेयर सिस्टम: मांस प्रसंस्करण स्वच्छता को बढ़ाने के लिए रोगाणुरोधी टीपीयू कन्वेयर बेल्ट पर शोध में निवेश करता है।

ये नवप्रवर्तक भौतिक उन्नति, संरचनात्मक अनुकूलन और प्रौद्योगिकी एकीकरण के माध्यम से विविध समाधान प्रदान करते हैं।

स्वच्छता समय को कम करने के लिए व्यावहारिक नवाचार

स्वच्छता अवधि को कम करना कई प्रभावी नवाचारों के माध्यम से प्राप्त किया जा सकता है:

का चयन आसानी से साफ होने वाला कन्वेयर बेल्ट डिजाइन

- सफेद पीयू बेल्ट जैसे सीमलेस, गैर-छिद्रित बेल्ट का चयन करें, जिससे अवशेषों का संचयन न्यूनतम हो जाएगा।

- ऐसे बेल्ट का चयन करें जो उच्च तापमान और कठोर रासायनिक कारकों का सामना कर सकें, जिससे स्थायित्व और स्वच्छता प्रभावशीलता सुनिश्चित हो सके।

- "आसान-सफाई बेल्ट" जैसे नवोन्मेषी उत्पाद उन्नत सामग्रियों और सतह उपचारों का लाभ उठाते हुए स्वच्छता और डाउनटाइम में भारी कटौती करते हैं।

बेल्ट संरचनाओं और स्थापनाओं का अनुकूलन

- मॉड्यूलर कन्वेयर बेल्ट डिजाइन त्वरित निराकरण और सफाई की सुविधा प्रदान करता है।

- तनावरहित कन्वेयर बेल्ट प्रणालियां मशीन डिजाइन और सफाई प्रक्रियाओं को सरल बनाती हैं, जिससे समग्र जटिलता कम हो जाती है।

- एलीगेटर® प्रणाली जैसे यांत्रिक बेल्ट फास्टनर त्वरित स्थापना और सरलीकृत स्वच्छता को सक्षम करते हैं।

उन्नत स्वच्छता प्रौद्योगिकियों को अपनाना

- पराबैंगनी (यूवी) स्वच्छता प्रणालियाँ: स्टेरिबेल्ट प्रणाली जैसे समाधान सतह की प्रभावी नसबंदी प्रदान करते हैं, तथा पारंपरिक स्वच्छता विधियों का पूरक या उनका स्थान भी ले सकते हैं।

- क्लीन-इन-प्लेस (सीआईपी) प्रणालियाँ: स्वचालित सफाई प्रक्रियाएं मैन्युअल श्रम और सफाई अंतराल को काफी कम कर देती हैं, जिससे संपूर्ण सफाई सुनिश्चित होती है।

स्वच्छता प्रक्रियाओं को बढ़ाना

- पुनरुत्पादनीय प्रभावशीलता के लिए तैयारी, स्वच्छता अनुक्रम और सैनिटाइज़र संपर्क समय का विवरण देते हुए व्यापक और मानकीकृत स्वच्छता प्रोटोकॉल विकसित करें।

- सैनिटाइज़र की तैयारी और उपयोग के बीच अंतराल को न्यूनतम करें, जिससे प्रभावकारिता अधिकतम हो।

- अत्यधिक या गलत रसायनों के प्रयोग से बचें, जो उपकरणों को खराब कर सकते हैं और भविष्य में सफाई को जटिल बना सकते हैं।

इष्टतम कन्वेयर बेल्ट सामग्री का चयन

नॉन-स्टिक बेल्ट सामग्री अवशेषों के चिपकने को काफी कम कर देती है, जिससे सफाई प्रक्रिया सरल हो जाती है।

रोगाणुरोधी टीपीयू बेल्ट सक्रिय रूप से बैक्टीरिया की वृद्धि को रोकते हैं, जिससे खाद्य सुरक्षा का गहरा आश्वासन मिलता है।

निष्कर्ष

मांस प्रसंस्करण में कन्वेयर बेल्ट की प्रभावी स्वच्छता खाद्य सुरक्षा सुनिश्चित करने और परिचालन दक्षता को अधिकतम करने के लिए अत्यंत महत्वपूर्ण है। सामान्य स्वच्छता चुनौतियों का समाधान करके, नवीन वैश्विक समाधानों को अपनाकर, और उन्नत सामग्रियों, संरचनात्मक अनुकूलन, स्वच्छता तकनीकों और मानकीकृत प्रोटोकॉल का उपयोग करके, व्यवसाय डाउनटाइम को काफी हद तक कम कर सकते हैं और समग्र उत्पादकता बढ़ा सकते हैं। अंततः, ये नवाचार खाद्य गुणवत्ता की रक्षा करते हैं, उपभोक्ता विश्वास को बढ़ाते हैं, और महत्वपूर्ण आर्थिक लाभ प्रदान करते हैं। इन सुधारों में निवेश खाद्य प्रसंस्करण कार्यों में उत्कृष्टता और सुरक्षा के प्रति निरंतर प्रतिबद्धता का प्रतीक है।

क्या आप अपने कन्वेयर बेल्ट की स्वच्छता में सुधार करने के लिए तैयार हैं?

👉 आज ही हमारे स्वच्छता विशेषज्ञों से संपर्क करें! जानें कि किस प्रकार हमारे अनुकूलित समाधान आपके मांस प्रसंस्करण कार्यों की दक्षता, सुरक्षा और लाभप्रदता को बढ़ा सकते हैं।

[अपना निःशुल्क स्वच्छता मूल्यांकन का अनुरोध करें ➜]